Commercial applications generally need to condition high quantities of ventilation air, and it is efficient to combine a desiccant rotor after a pre-cooler and use the waste heat to dry the desiccant, which creates a much lower dew-point and free reheat effect. The air can be dried sufficiently lower than the room set-point to allow for internal latent moisture loads.

SELECTION

Example. For 10,000m3 /h Chilled water DOAS (Dedicated Outside Air) unit needs 5C off coil and a Desiccant-DOAS system requires 12C and 84kW Condenser heat/hot water to maintain 23C 50%rh assuming 7.5l/s and 60W person . This saves 130kWR and the increase in water temperature of 4-5C improves an air cooled chiller COP by 10%.

STEP1 Number of building occupants?

- Local codes have a minimum OA quantity

- USA 15cfm per person

- AUSTRALIA 7.5 l/s per person

- Eg 400people x 7.5l/s pp = 3000l/s (10000cmh)

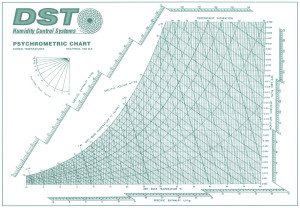

STEP 2 OA design condition

Important to know for chilled water capacity check eg35CDB 24CWB

STEP 3 Room humidity ratio

- 50%rh 23C library 8.8g/kg

- 60%rh 23C commercial building

- 50%rh 23C (or other) Supermarket 8.8g/kg

- 60%rh at 28C swimming pool

STEP 4 People x nominal load

100g/h pp Eg 400 x 100g/h = 40kg/h NOTE 40kg/h x .683 = 28 kW latent

STEP 5 Internal infiltration rate

Best to take extra consideration as over design may occur in commercial projects. This can be data provided by consultant (design institute), including external duct work, 1% leakage rate or from customer on large systems, or some estimate based on DST How much OR Munters guide for small rooms

- Tight 0.1 cfm/ft2 A(8.8cmh/m2).

- Average 0.3 cfm/ft2(25cmh/m2)

- Loose 0.6 cfm/ft2 (50cmh/m2)

Moisture Load

Room 20 x 20 x 3 (A= 20×20=400m2) = cmh/m2 x m2 x 1.2 x Design day g/kg – Room g/kg

=8.8 x 400 x 1.2 x (14-8.8)/1000

=23kg/h (USA btu/hr= .68 x cfm/ft2 x (design day HR – space HR)

NOTE: DST how much selection factor 3 equated to 1200cmh

It is advisable to make selection based on moisture from people alone, if it is below

STEP 6 Calculate Humidity ration Δg/kg

Fresh air delivered this much dryer than room dew-point

= internal load (Q4+Q5kg/h) / (OA m3/h x ρ kg/m3) x1000

= (40+23)/(10,000x 1.2) =5.25g/kg (NOTE 3.3g/kg on moisture from people alone)

STEP 7 : REQUIRED OA Supply HR g/kg

SA HR = Room HR(step3) – Δg/kg(step6)

ie Supermarket : SA HR= 8.8-3.5=5.3g/kg OR 4.5C dew-point (Cant be done reliably by chilled water or DX alone.) Usually desiccant duty around 3.5g/kg so off pre cooling coil using desiccant 8.8g/kg or 12Cdp.

Desiccant dehumidification has had substantial application into commercial buildings in humid climates due to operating and compliance requirements of the case manufacturers, and the inability of conventional HVAC to dehumidify effectively