Comparison of DH technologies

The basic principle of Dehumidifiers is that they remove moisture from the air by drawing the air into a medium (A) the desiccant wheel to absorb vapour from the air, or (B) refrigeration evaporator, and cooling the air below its dew point, where the water condenses and is then removed from the system.

The Desiccant wheel is a highly absorbent material, which easily attracts the water vapour in the air as it flows through it. Then using the return air from the space, the moisture is taken out of the unit and outside in an energy-efficient method. As you can see below, the air is loaded with water vapour on the way into the desiccant wheel, and upon leaving the wheel it is significantly drier.

The refrigerant dehumidifiers use a similar technique, but water vapour is removed by cooling the air to below its dew point (the temperature at which it begins to turn to water droplets) and turning into the water on the cold condenser fins. These water droplets then fall into a drip tray below, and the water is removed from the system. The air is then reheated on a condenser and cycled into the space.

Comparison of refrigerant and Desiccant dehumidifiers

With our understanding of Master Refrigeration and Comparison with DST cost and energy, we can share a suitable solution for you. Usually, the question is do you need humidity control below 50 – 60% in below 18C? Refrigeration is better in warmer humid conditions and the desiccant will system is better for lower humidity and dew-points as discussed below.

Ask us to compare your condition

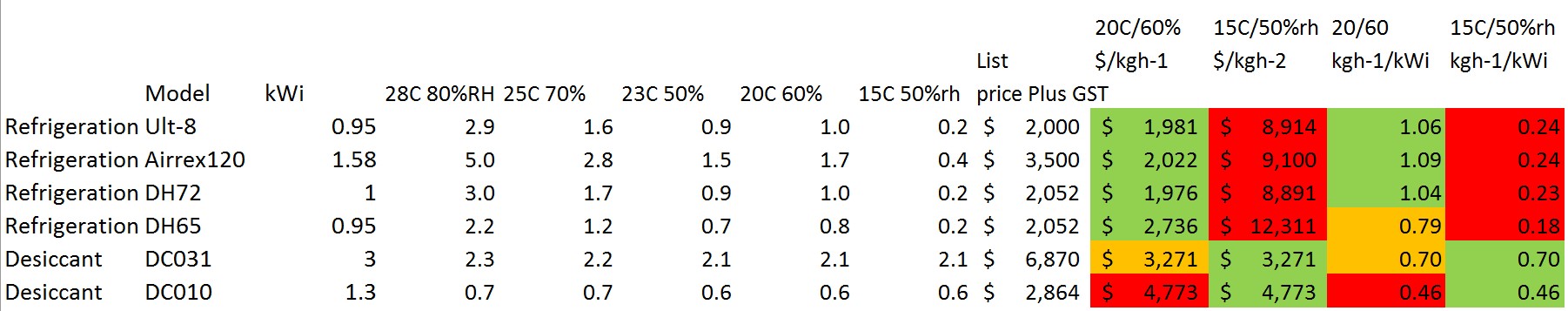

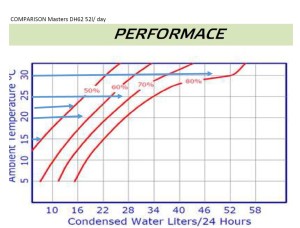

The table demonstrates the diminished performance of refrigeration capacity at controlled room conditions

Q’s and A’s

How often will I need to replace the desiccant rotor?

The desiccant rotor is the heart of the dehumidifier and our silica gel rotors have a 3-year warranty on performance. The rotor will normally out-live other mechanical components. Some chemicals can, on rare occasions, have a detrimental effect on silica gel as can contaminated air, so if in doubt – ask. In general, we can say that our rotors will operate effectively for at least 10 years.

Can I wash the rotor?

Although the rotor is washable in water or acid-based detergent, this is carried out as a last resort and is not included as part of the maintenance routine. Although the procedure is relatively straightforward, do not attempt this without consultation. To avoid contaminating the rotor it is essential that air filters are regularly maintained.

How is the dehumidifier capacity controlled?

The rotor will only absorb moisture if it is being continually reactivated. The level of reactivation is dependant on both the reactivation air volume and the reactivation temperature. Full capacity is achieved when the reactivation temperature is between 120°C and 140°C at the nominal airflow. In most cases the reactivation airflow is commissioned at a constant volume, so the drying capacity would be controlled by regulating the air temperature. In steam reactivated units the airflow can be controlled as the steam flow itself regulates.

How do I drain condensate from the unit?

You don’t. There is no condensate – so no problems with freezing either. All the moisture is removed from the system as water vapour. The wet air outlet is warm and wet (similar to a tumble dryer outlet) – another reason why desiccant dehumidifiers work much better at lower temperatures.

Electricity is expensive, so what other options are there?

About 90% of the energy used on a desiccant dehumidifier is for heating the reactivation air. All our single phase units operate using electric reactivation only. On larger dehumidifiers, there is a choice of steam, direct-fired gas (natural and LPG) or hot water – all of which should reduce running costs. Also see our bespoke Flexisorb system, where a combination of different heaters can be used.

Why is the dry air outlet so warm?

Most of the heat gain is due to the exchange of energy (enthalpy) during the adsorption process. Some heat is transferred from the hot reactivation sector. In our Recusorb systems, this is minimised by the inclusion of a heat recovery (purge) sector.

Why does the wet air outlet duct feel hot?

As the hot reactivation air picks up moisture from the rotor it is cooled (exchange of enthalpy). Normally the wet air outlet is around 50°C. If the amount of available moisture in the rotor is reduced, then the wet air temperature rises. The wet air temperature alarm is normally set at 70°C to 80°C. Should the rotor drive system fail, the wet air outlet temperature will rise rapidly due to the reduction of enthalpy exchange across the reactivation sector.

Should I use a heat exchanger on the wet air outlet?

The Recusorb system utilises a unique internal heat recovery system as standard. The incoming reactivation air is passed through 15% of the rotor face, gaining some 30% of the total reactivation heat required. The heat recovery sector preheats the reactivation air to about 70°C before the heater, thus increasing the overall efficiency of the drying process. There would be nothing gained by installing a cross-flow heat exchanger to this system as the wet air outlet temperature is usually lower than the temperature leaving the heat recovery sector.

Which ducts require insulating?

The wet air duct carries moisture-laden air which can have a dewpoint in excess of 30°C. On cold days, condensation can easily occur inside the duct. While insulation will help prevent this, as additional protection against condensate running back to the unit, the duct should either slope away from the dehumidifier or a small drain hole drilled at a duct low point. Insulation of other ducts is optional – depending on system air temperatures.

Questions relating to Refrigeration dehumidifiers

How does a refrigeration dehumidifier work?

It works by first passing the air across the cold evaporator coil that cools it to a point where condensation occurs, then across the warm condenser coil which heats it. Condensation formed on the evaporator coil drips into a collection tray where it is either drained away or collected in a container in the base of the unit.

How can a dehumidifier provide “Free” heat?

The effectiveness of the dehumidifier depends upon the relative humidity (RH) of the incoming air. The slightest cooling of air which is at 100%RH will result in water being condensed. Latent heat rejected by the water during its change in state from a vapour to a liquid is transferred by the refrigerant gas to the condenser to provide “free” heat. At low relative humidity, the air needs to be cooled down to its dewpoint before any water is released. In this case, much of the refrigerant cooling goes into lowering the air temperature and only a small part is left to remove moisture. If no moisture is being removed, there will be no “free” heat. I’ve purchased a dehumidifier from a DIY store.

Why does my unit not produce 15 litres/day as stated on the box?

Most manufacturers of refrigeration dehumidifiers will state moisture removal when operating at 30°C, 80%RH (22.0 g/kg). However, at these extreme levels, refrigeration units will be operating at their highest efficiency and unless the dehumidifier is actually being operated under ‘tropical conditions’, the real capacity will be a lot less. Typically, the performance once in a controlled space of 20°C, 60%RH is relevant, the same model will have much lower efficiency and is likely to extract only 1/3rd (33%) of that indicated on the box – so buyers beware! To put this unit performance rating into erspective:-Average climatic conditions in Sydney is 18°C, 80%RH which equates to just 11 g/kg (15°C dewpoints) max 17g/kg

How does temperature and humidity affect performance?

As the surrounding air becomes drier its dewpoint is lowered, so the temperature necessary to create condensation on the cold evaporator also becomes lower. If the dewpoint of the incoming air is already below 10°C, the evaporator coil temperature necessary to create condensation is likely to be sub-zero. As airborne water vapour makes contact with the cold tube surface the condensate will begin to freeze. Ice build-up on the evaporator coil restricts heat transfer and airflow, thereby reducing the overall operating efficiency of the unit.

My refrigeration dehumidifier has a minimum operating temperature of 3°C … what does this mean?

Units that can operate at lower temperatures will normally have a defrost cycle. When the unit switches to defrost mode, hot refrigerant gas is put directly into the evaporator coil, which melts ice build-up. The unit will not be able to dehumidify during the defrost cycle. Despite many dehumidifiers having a defrost system, at dew points below 10°C to 12°C (depending on machine quality), extraction rates are typically minimal and efficiencies very low. This will increase operating costs. Refrigeration dehumidifier or desiccant dehumidifier (non-process)On the psychrometric chart draw a horizontal line at 10°Cdp (7.6 g/kg) and another at 12°Cdp (8.7 g/kg). As a general guide, if the required room condition falls anywhere below the 10°Cdp line, use a desiccant dehumidifier, whereas above the 12°Cdp line a refrigeration type may be more appropriate. If the required condition falls between these lines, a desiccant dehumidifier will probably be more effective but a quality refrigeration dehumidifier may also be considered.