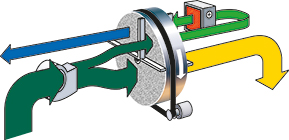

The Consorb principle is normally

The Consorb principle is normally

used at low regeneration

temperatures, e.g. if you have

surplus heat or when dehumidifying

very damp air. The Consorb principle

is also good when there is a large

difference in moisture content

between process and regeneration

air inlets.

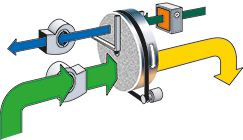

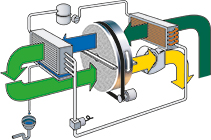

Recusorb R has an internal heat

recycling. During the rotor’s

regeneration heat is absorbed,

and then recycled in the “purge

zone”, where incoming air is

preheated and partly dehumidified.

Energy consumption falls and the

dry air becomes both drier and

cooler compared to other sorption

dehumidifiers.

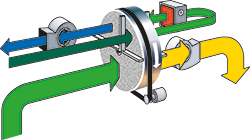

Recusorb DR has an internal heat

recycling with, one fan produces

both the dry airflow and the wet

airflow. This makes installation

simpler when there is a need for

overpressure in the room to be

dehumidified. This principle is also

suitable for very low dew points.

Aquasorb basically functions as

a Consorb, but the wet air flow is

condensed in an air-cooled condenser instead of being exhausted

out. No need for exhausting out wet

air from the dehumidified room. All

energy put into the unit stays also in

the room, which is good for drying

applications.

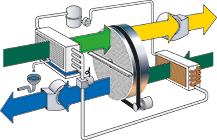

Econosorb combines a heat pump

with the sorption rotor in a unique

way, providing very low energy

consumption and a low dry air

temperature. Probably the most

energy efficient dehumidifier on

the market, with approximately 1/4

of the total energy consumption

of regular sorption dehumidifiers.

Econosorb has both condensation

and wet air flow.

Frigosorb is used in applications

where it is difficult to remove a wet

air flow. Thanks to the heat pump

function Frigosorb is very energy

efficient, using approximately 1/3

of the total energy consumption of

regular sorption dehumidifiers.

Important – Wet Air Outlet duct arrangement for all desiccant dehumidifier installations

Important – Wet Air Outlet duct arrangement for all desiccant dehumidifier installations