Can wet or humid conditions impact Lithium battery manufacturing?

Yes. Pure lithium reacts violently with water which can result in transformation into lithium hydroxide and hydrogen.

Uncontrolled humidity or temperature alone may compromise the separator’s integrity leading to a short circuit and thermal runaway.

How to maximise the quality of Lithium Battery production?

Battery processing must take place in an ultradry room where the dew point is controlled at a very low humidity level and there is attention to filtration and infiltration. For this highly sensitive process, the use of a desiccant dehumidifier is essential.

How to control humidity in Lithium production?

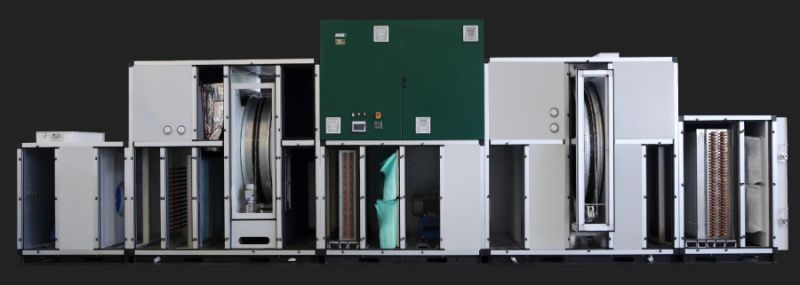

DST desiccant technology is a unique configueation and uses low energy. Production rooms are transformed into clean rooms where ventilation is mixed with return air and treated by dehumidifiers for -60Cdp supply air, to create a room of 1%rh (-40Cdp), in a complete package Desiccant system.

This approach ensures that both temperature and humidity are controlled by the same unit.

One rotor configurations are available for -50Cdp and more standard units for -40Cdp, but can provide leakage risk and lost performance over time, and higher energy consumption, so these are used in less critical Dry rooms such as plate freezers.

DST are the market leaders in the design and supply of ultra-low humidity air systems for battery manufacturing clean rooms. By 2023, DST and Seibu Giken technology has more than 2000 Li-battery installations for 1%RH. A dry air supply at 0.05%RH at 20°C (-60°Cdp) can be achieved using our standard D-Max silica gel rotor.

The main projects we have done in Europe and USA are Tesla Germany, Tesla USA and CATL Germany.

DST – Seibu Giken Li-Battery Improvement

The processes used for manufacturing Lithium-ion batteries are very similar to those used in the production of Nickel Cadmium cells and Nickel Metal Hydride cells. The anodes and cathodes in Lithium cells are of similar form and are made by a similar process. There are however some key differences associated with the higher reactivity of the chemicals used in the Lithium cells.

The electrolyte filling and sealing stage of cell manufacture must be carried out in a “dry room” since the electrolyte is highly reactive with moisture. Moisture causes the electrolyte to decompose with the emission of toxic gases.

One of the most commonly used electrolyte materials, Lithium Hexafluoride, forms toxic hydrofluoric acid (HF), Lithium Hydroxide and Hydrogen Gas when exposed to moisture.

Crucially, moisture sealed inside the battery can continue to react after the battery is completed, significantly reducing its lifespan.

???? https://dstdryer.com.au/

✉️ info@dstdryer.com.au

???? 1300002288